Product Features• Address writing and reading of the field devices.• Configuration setting function for field devices.• Test and control field devices.• Automatic address+1 when addressing devices consecutively.• Support connection of external power supply.• Alarm with low voltage.• Switchable Chinese/English interface.Technique Data• LCD: 128X64 lattice• Working voltage: DC5V• Standby power: 130mW• Maximum power consumption: 380mW• Working power supply: 5#AA NI-MH battery ×4 or through Micro USB interface.Descriptions and Instructions• Power on: press the "function key" to power on, and the function menu appear. Select the function by "up"

to power on, and the function menu appear. Select the function by "up" or "down"

or "down" and press "enter"

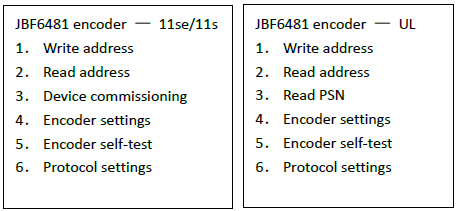

and press "enter" .The menus of different protocols are slightly different. Press the corresponding number key to enter the wanted function menu.

.The menus of different protocols are slightly different. Press the corresponding number key to enter the wanted function menu.• Protocol Settings: select the corresponding protocol according to different device models. Select "protocol settings" menu, and select 11S, 11SE, 61S or UL according to the corresponding number.

| Serial | protocol | Compatible product |

| 1 | 11SE | Fire alarm system, gaseous fire suppression system with exceptions of JBF4000, JBF4100, JBF4110, JTY-GD-JBF-3100, JTY-GD-JBF-3100-Ex , JTW-ZD-JBF-3110, JTW-ZD-JBF-3110-Ex, JBF-131F-N, JBF-141F-N, JTY-GD-LN2100, JTW-ZD-LN2110, J-SAP-M-JBF-101F, JBF-131F, JBF-141F, JBF-137D |

| 2 | 61S | Fire door system, power supply monitoring system, electrical fire system |

| 3 | UL | UL series product |

| 4 | 11S | Fire alarm system, gaseous fire suppression system |

• Write address: select "write address" function, and enter the write address function process. Press the number key to enter the address number, and then press the "enter" to confirm the writing. After successful address writing, there will be a beep sound, and the address number will automatically add 1 for next writing. The display screen shows "success". If the writing fails, there will be two beeps and the word "failed" appear on screen. Press "delete"  to write another address again. Press function key

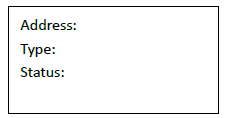

to write another address again. Press function key  to return to the main menu.• Read address: select the read address menu. After entering the address reading process, press "enter" to read the address of the field part. After reading, the address is displayed on the interface, and there will be a beep. If the read fails, '000' is displayed. Press the function key to return to the main menu interface.• Part debugging: optional function - query type, batch test, single test.

to return to the main menu.• Read address: select the read address menu. After entering the address reading process, press "enter" to read the address of the field part. After reading, the address is displayed on the interface, and there will be a beep. If the read fails, '000' is displayed. Press the function key to return to the main menu interface.• Part debugging: optional function - query type, batch test, single test. • Query type: you can query the type of field parts. Up to 16 field parts can be read at the same time. After entering the menu, wait for 3S and press "enter" .

.

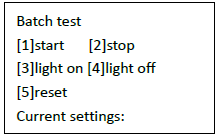

Batch test: perform start, stop, light on, light off and reset operation on field parts. Up to 30 field parts can be operated at the same time (24V power supply is needed for four-wire system equipment).Press the corresponding number key and then press "enter"  to execute the instruction;

to execute the instruction; • Single test: perform query on a specific field device on the loop.

Connect the encoder straight to the loop. The number of connected devices should be less than 30.

Enter the address number of the target device and press “enter” to read the type and state of the target device. The corresponding instructions can be executed by "up"  or "down"

or "down"  keys.

keys. • Setting encoder: press the corresponding number key to set the backlight [on] or [off] and the automatic shutdown time.

• Encoder self-test: under this menu, press the button to detect whether the buttons are working normally. After pressing the button, the corresponding items should display normal.

• Function configuration: optional function - interface settings for fire doors, thermal electrical fire detectors settings, residual current module settings, and configuration data reading.

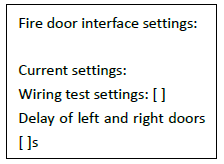

• Fire door interface settings: for fire door interface circuit check switch (1 is on and 2 is off) and delay time settings for left and right doors. After successful writing "current Settings" displays the latest written value.

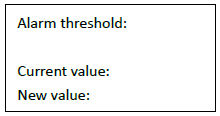

• Thermal electrical fire detectors settings: the alarm threshold value of the thermal electrical fire detector in the electrical fire system can be set. After typing the value, press "enter". After successful writing "current Settings" displays the latest written value.

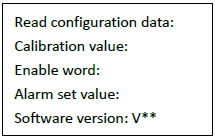

• Configuration data reading: read the calibration value, enable word, alarm set value and software version number (this function data is used for the on-site device test by our technical personnel)

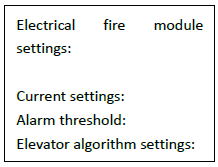

• Electrical fire module settings: The alarm threshold of residual current detector in the electrical fire monitoring system and the elevator algorithm switch (1 is on and 2 is off) can be set. The "current setting" will display the latest written value after successful writing.

Note: this function is only available for 61S protocol.• Reading PSN code of field devices to get their production date, serial number and other information.

Note: this function is only available for 61S and UL protocol.• Shutdown: long press "function" to shutdown encoder.

to shutdown encoder.

Note: in the above operation, the loop of the devices should not connect to the control panel. Otherwise, the equipment will be damaged!

to power on, and the function menu appear. Select the function by "up"

to power on, and the function menu appear. Select the function by "up" or "down"

or "down" and press "enter"

and press "enter" .The menus of different protocols are slightly different. Press the corresponding number key to enter the wanted function menu.

.The menus of different protocols are slightly different. Press the corresponding number key to enter the wanted function menu.

to write another address again. Press function key

to write another address again. Press function key  to return to the main menu.

to return to the main menu.