- Home

- About Us

-

Product

UL Fire Safety System

EN Fire Safety System

Automatic Fire Alarm System

Small-area Fire Safety System

Gaseous Suppression and Control System

Fire Door Monitoring System

Electrical Fire Monitoring System

Power Supply System for Fire Protection Equipment

Combustible Gas Detection and Alarm System

Wireless WAN Fire Safety System

-

JTY-GD-JBF5100

-

JBF4101-Bp

-

JBF4101-Ex

-

JTW-ZD-JBF5110

-

JBF4111-Bp

-

JBF4111-Ex

-

JTF-GOM-JBF-4000

-

JTY-GF-JBF-VH76

-

JTY-H-JBF4382

-

JTY-GD-JBF4103-Ex

-

JTW-ZD-JBF4113-Ex

-

J-SAP-JBF4121B

-

J-SAP-JBF4121B-P

-

J-SAP-JBF4121A-Ex

-

JBF4123B

-

JBF4123A-Ex

-

J-SAB-JBF4121G-Ex

-

JBF4123G-Ex

-

JBF1372E1

-

JBF4372E2

-

JBF5172

-

JBF4061

-

JBF5060

-

JBF5061

-

JBF4374-Ex

-

JBF293K

-

JBF-6481

-

JBF-195K

-

JBF-TD802

-

JBF-TD803

-

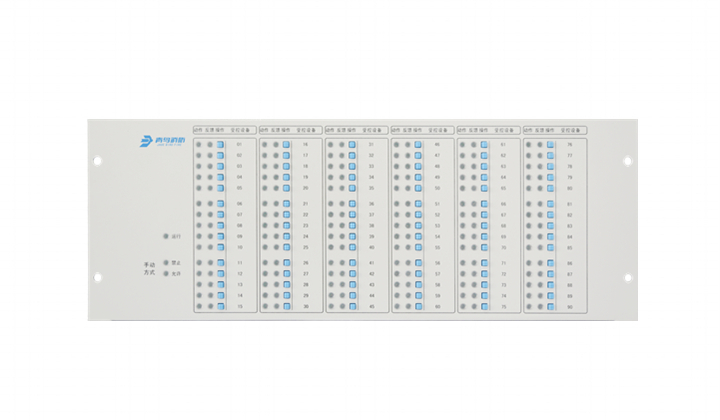

JBF5131

-

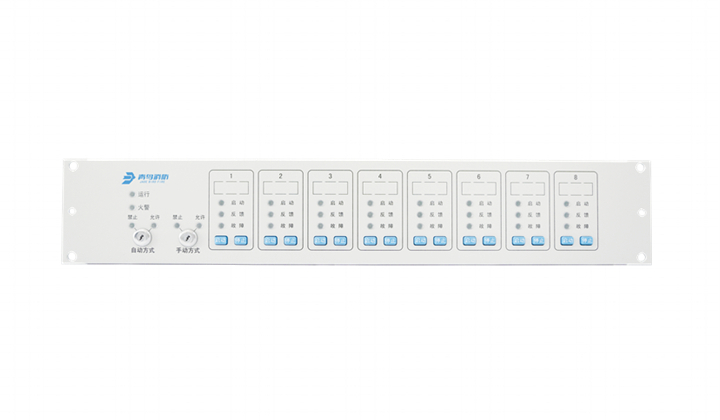

JBF5141

-

JBF5142

-

JBF4171

-

JBF4143

-

JBF5155

-

GRT3BM-01/GRT3XA-01/GRT3XM-01

-

JBF-11SF72

-

GRT-GB11-KZ

-

GRT-GB11-150/300/600

-

JB-QB-JBF5009

-

JB-QB-JBF5010

-

JB-QB-JBF5011

-

JB-QB-JBF5012

-

JB-TB-JBF-11SF-S/S8

-

JB-TG-JBF-11SF

-

JB-TT-JBF-11SF

-

JBF5200

-

JBF5202

-

JBF-11SF-CK90B

-

JBF-11SF-CD8B

-

JBF5174-EX

-

JBF6117

-

JBF6481-E

-

JBF5175

-

JBF5174

-

JTG-H-JBF4384-EX

-

Zener Safety Barrier

-

JTG-U-JBF4386-Ex

-

JTW-LD-JBF4310

-

JBF-FHX1, JBF-FHX2

-

JBF-FHH1, JBF-FHH2

-

JTG-Z-JBF4385-Ex

-

- Case

- Service

- News

- Download

- Contact Us