DESCRIPTIONThe FW521 is an intelligent Heat Detector UL listed device according to UL 521 and ULC-S530 for Fire Protective Signaling Systems for indoor use with both fixed-temperature alarm and rate-of-rise alarm characters. It features a slim design which combines visual appeal with a high standard of reliability. The detector has a Microcontroller Unit (MCU) performing comprehensive self-diagnostic tests, and result analysis. The FW521 is intelligent, addressable, and takes one address on the Signaling Line Circuit (SLC) of the fire alarm control panel.

ATTENTION

The products must be installed in accordance withNational Fire Alarm Code, NFPA 72, CAN/ULC-S524, National Building Code of Canada, National Fire Code of Canada, Local Codes and the Local Authorities Having Jurisdiction. Prior to installing bases, make sure the product will have sufficient margin and wiring room. Do not over tighten the mounting screws to avoid base deformation, which may affect the detector efficiency. Check information of equipment used in the system by other manufacturers for any guidelines or restrictions.

The detector should never be installed in the following locations: near fireplaces, furnace rooms, etc.

NOTE

Do not paint this device.Any material extrapolated from this document or from Maple Armor’s instructions or other documents describing the product for use in promotional or advertising claims, or for any other use, including description of the product’s application, operation, installation, and testing is the sole responsibility of the user. Maple Armor will not assume any liability for such use. In no case will Maple Armor’s liability exceed the purchase price paid for a product.

SPECIFICATION

| Nominal Voltage | 24VDC |

| Voltage Range | 17.6 to 28VDC |

| Standby Current | 0.1mA |

| Alarm Current | 1mA |

| Fixed Temperature Rating | 135°F (57.2°C) |

| Rate-of-Rise Detection | 15°F/min. (8.3°C/min.) |

| Installation Temperature | 32°F to 100°F (0°C to 38°C) |

| Operating Humidity | 0% to 93% RH |

| Diameter | 4.13 in. (105mm) |

| Height (with base) | 1.87 in. (47.5 mm) |

| Weight (with base) | 4.3 oz (121 g) |

| Mounting | FW500 Base |

| Mounting Orientation | Ceiling only |

| Spacing | 50 feet (15 m) |

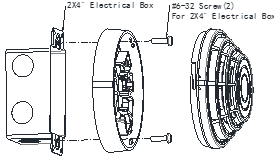

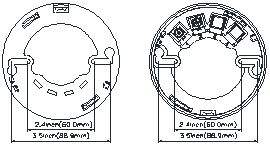

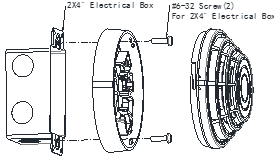

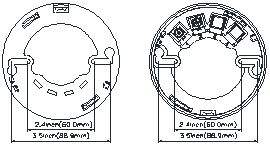

1.Mount the FW500 base onto a 2x4’’ electrical box, see Figure 1. The installation hole pitch is illustrated in Figure 2.

Figure 1. FW500 Base Installation Figure 2. Wiring Terminals and Pitch of Hole

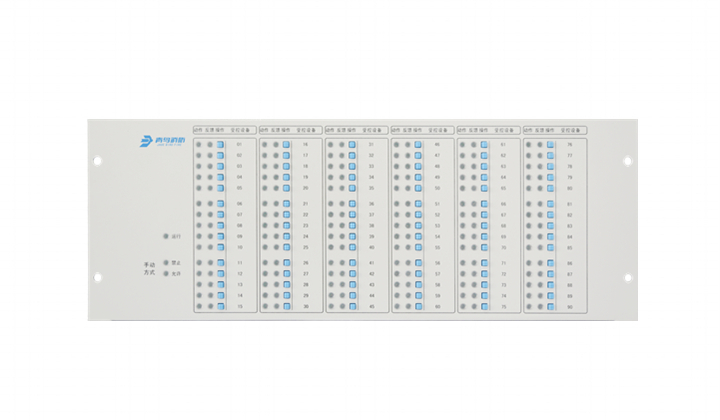

2.Wire the SLC to the detector base, as illustrated in Figure 3. There is no polarity distinction between terminal 1 and terminal 2.

.jpg)

.jpg)

Figure 3. Wiring Diagram-(a) Class A Circuit Figure 3. Wiring Diagram-(b) Class B Circuit

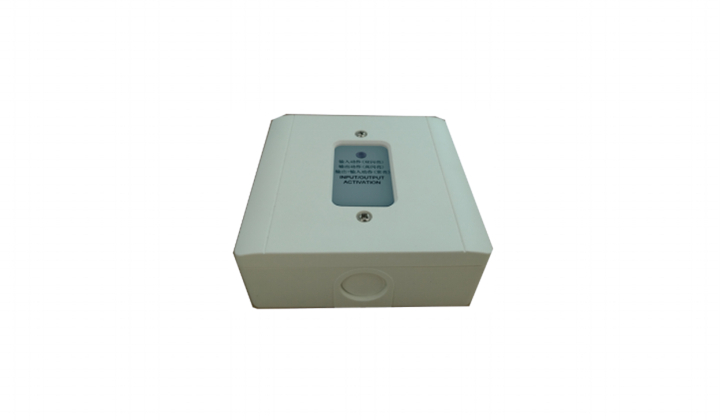

3.Set the detector address (1-252). Use the hand-held Programmer ReadWritor FW411. Refer to the FW411 Manual. 4.Put the detector onto it’s base and secure it into position by turning clockwise.

5.Apply power to the control unit to activate the SLC.

TESTING1.Before testing, inform the proper authorities that the system is undergoing maintenance and will temporarily be put out of service.

2.Disable the system to prevent unwanted alarms.

3.Make sure the indicator LED on the detector’s surface is flashing. Failure to flash indicates a non-functioning detector or a faulty wiring.Check the wiring and remount the detector.

4.Heat the detector using a blower. The LED should turn to steady lighting when ambient temperature reaches the alarm threshold.

5.After the detector cools down, reset the detector from the control panel.

6.Once the testing is completed, set the system back to normal operation and inform proper authorities.

MAINTENANCE

Return the detector for reparation if it fails to flash or alarm during testing. Do not disassemble the detector without permission.

.jpg)

.jpg)