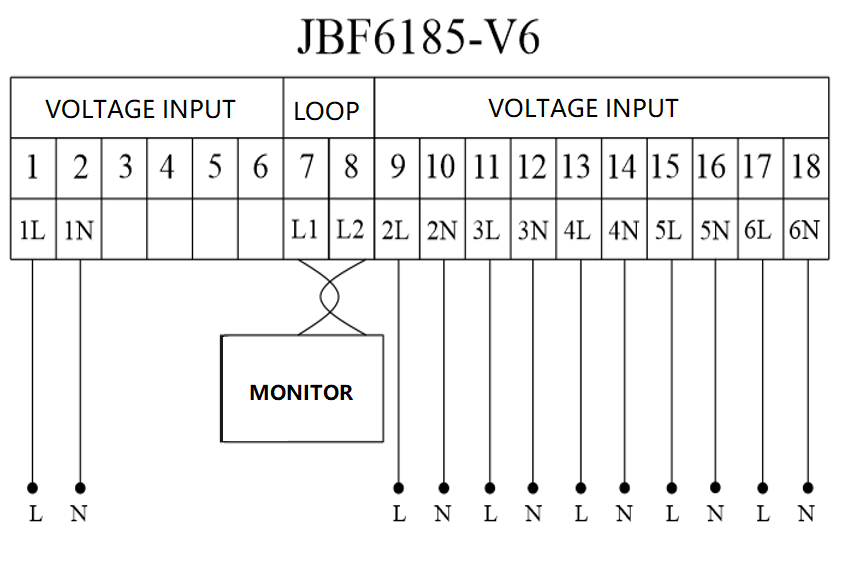

JBF6185-V6

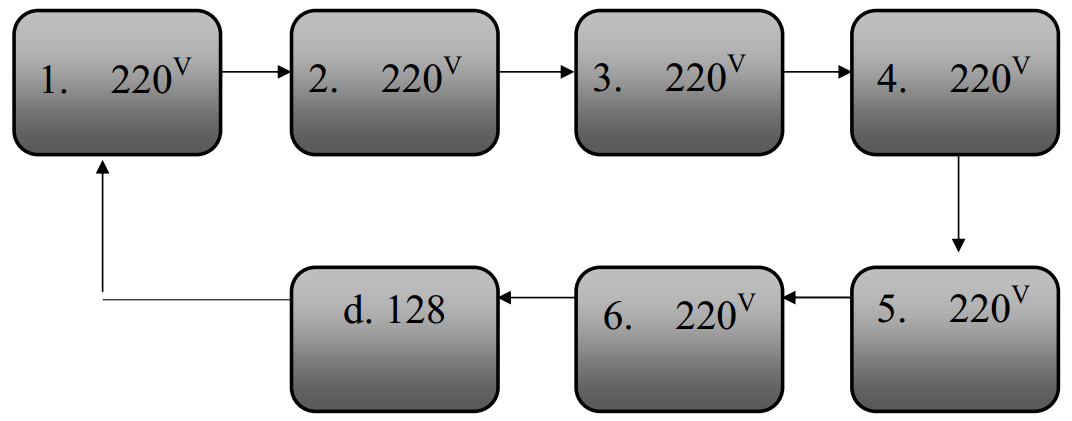

Two-wire, non-polar, monitoring six routes of the voltage of single phase power supply of fire equipment in real time, rotary display.

| Content | Technical Parameters |

| Specification | Monitor for 6 lines |

| Monitored object | Voltage value of single phase AC power |

| Rated voltage | DC24V (loop powered) |

| Working current | 5mA |

| Rated voltage Monitoring | AC220V |

| Voltage resolution | 1V |

| Percentage of overvoltage | 0%~20% |

| Percentage of under-pressure | 0%~20% |

| Wiring | Two-wire, polarity-free |

| Communication distance | ≤1500m |

| Working environment | Temp: 0℃~+40℃; Humidity: 10%~93% (non-condensation) |

| Dimensions | 132mm×99.5mm×58mm (L×W×H) |

| Installation | 35mm standard rail |