FW511

UL listed, two-wire, non-polar, quick respond to smoke produced by different combustible material. The built-in high-performance microprocessor can self-test, analyze and diagnose the detector state.

| Nominal Voltage | 24VDC |

| Voltage Range | 17.6 to 28VDC |

| Standby Current | 0.14mA |

| Alarm Current | 1mA |

| Smoke Sensitivity | 1.6%/ft to 2.3%/ft |

| Operating Temperature | 32°F to 100°F (0°C to 38°C) |

| Operating Humidity | 0% to 93% RH |

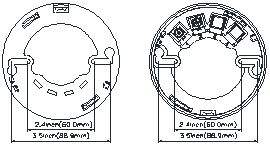

| Diameter | 4.13 in. (105mm) |

| Height (with base) | 1.87 in. (47.5 mm) |

| Weight (with base) | 4.6 oz (132 g) |

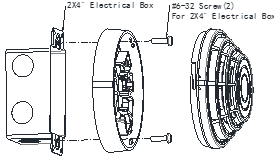

| Mounting | FW500 Base |

| Mounting Orientation | Ceiling, wall |

| Spacing | 30 feet (9.1 m) |

.jpg)

.jpg)