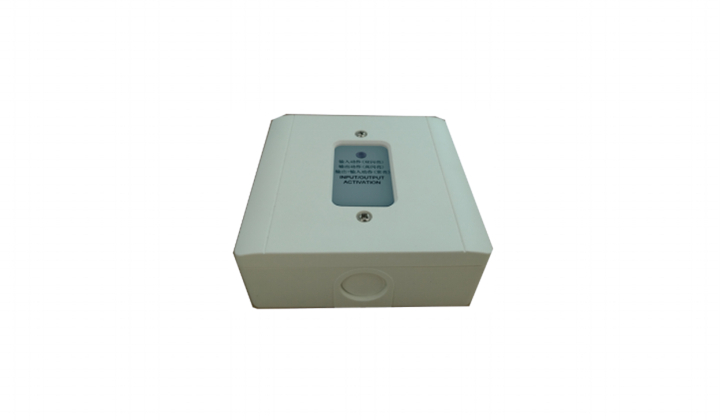

DESCRIPTIONThe FW811 input module monitors a single contact. The input line is monitored for open line faults and ground faults, and the contact must thus be wired with an end-of-line resistor. It is an intelligent addressable module and takes one address on the Signaling Line Circuit (SLC) or Data Communication Link (DCL) of the fire alarm control panel. The FW811 is a UL listed device according to UL864 and ULC-S527 for Fire Protective Signaling Systems for indoor use. The type of the input contact is configurable.

Alarm Causing: An alarm causing input will produce an ALARM event. The device LED will indicate the alarm condition by red steady on. A return to normal condition will be ignored and the device LED indicator will remain latched in the red alarm condition until a reset command has been received.

Supervisory/Trouble/Monitor Causing: By changing the FW811 input module functions from its attribute interface on FACP, it can be configured to be a supervisory, trouble, or monitor signal, which will produce a SUPERVISORY, TROUBLE, or MONITOR event. The device LED will indicate the event condition by red steady on. The supervisory and monitor are latched/non-latched selectable. A return to normal condition will cause the event to disappear and the device LED indicator will return to the normal condition if the supervisory/monitor is non-latched. A return to normal condition will not cause the event to disappear and the device LED indicator will remain in event condition if the supervisory/monitor is latched. The trouble is non-latched.

ATTENTION

The products must be installed in accordance with the NFPA 72, the CAN/ULC‐S524, the CAN/ULCS536, and the Canadian Electrical Code depending on the country of installation. Check information of equipment used in the system by other manufacturers for any guidelines or restrictions.

NOTE

Do not paint this device.

Any material extrapolated from this document or from Maple Armor’s instructions or other documents describing the product for use in promotional or advertising claims, or for any other use, including description of the product’s application, operation, installation, and testing is the sole responsibility of the user. Maple Armor will not assume any liability for such use. In no case will Maple Armor’s liability exceed the purchase price paid for a product.

SPECIFICATION

| Nominal Voltage | 24VDC |

| Voltage Range | 15 to 28VDC |

| Standby Current | 0.17mA |

| Alarm Current | 0.79mA |

| Max. Line Impedance | 25 Ω |

| Max. Impedance for Grounding | 6.6 KΩ |

| Compatible EOLR | FW421 (10KΩ) |

| Operating Temperature | 32°F to 120°F (0°C to 49°C) |

| Operating Humidity | 0% to 93% RH |

| Mounting | FW800 base |

| Dimension | 120 mm (L) x 120 mm (W) x 45 mm (H) |

| Weight (with backbox) | 8.7 oz (247 g) |

| Wiring Gauge | 12 to 18 AWG |

INSTALLATION

1.Mount the FW800 base onto a 2X4 or 4x4 electrical box using the screws provided, as illustrated in Figure 1.

Figure 1. Installation Diagram

2.Connect the wires, see Figure 2. There is polarity sensitive between terminal 1 and terminal 2. All circuits are power-limited.

Figure 2. Wiring Diagram (SLC/DCL)

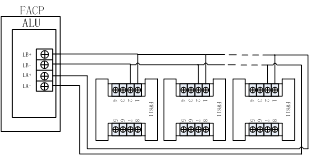

3.Wire the SLC/DCL to the module, as illustrated in Figure 3.

(a) Class A or DCLA Circuit (b) Class B or DCLB Circuit

Figure 3. SLC/DCL Wiring Diagram

4.Connect the input line circuit wires. See Figure 4. The maximum line impedance for input circuit is 25Ω.

(a) Class A Circuit (b) Class B Circuit

Figure 4 Wiring Diagram (Input Line Circuit)

5.Combine the assembled unit to the base using the screws provided.

6. Apply power to the control unit.

PROGRAMMING

The module must be programmed to a valid address before use. A valid must be in 1~252 and cannot be duplicate with other device in same loop. Refer to the manual of hand-held programmer ReadWritor FW411 and Panel FW106 to set the device address. Disconnect wire at terminal 1 and 2 before programming.

TESTING

1.Before testing, inform the proper authorities that the system is undergoing maintenance and will temporarily be put out of service. Disable the system to prevent unwanted alarms.

2.Make sure the indicator LED on the detector’s surface is flashing. Failure to flash indicates a non-functioning detector or a faulty wiring. Check the wiring and remount the detector.

3.Trigger the input switch to activate a fire alarm/ supervisory/trouble/monitor signal. The LED should turn to red steady on. Check the event occurrence displayed on LCD of the controller and verify it.

4.Once the testing is completed, set the system back to normal operation and inform proper authorities.

MAINTENANCE

Return the module for repair if it fails to flash or alarm during testing. Do not disassemble the module without permission.

.jpg)

.jpg)